Driving Efficiency in Industrial Sectors

The industrial sector, a cornerstone of global economies, constantly seeks ways to enhance its output and resource utilization. Driving efficiency is not merely about doing more with less; it involves a holistic approach to optimizing every facet of operations, from initial raw material acquisition to the final product delivery. This pursuit of greater efficiency is critical for maintaining competitiveness, fostering innovation, and ensuring sustainable growth in an ever-evolving market landscape.

Enhancing Manufacturing and Production Processes

Modern industrial landscapes place a significant emphasis on refining manufacturing and production processes to achieve higher levels of efficiency. This often involves adopting methodologies such as lean manufacturing, which focuses on eliminating waste in all forms, from overproduction to unnecessary motion and defects. By scrutinizing each step of the production line, businesses can identify bottlenecks, reduce lead times, and improve the overall quality of output. The integration of advanced technology, such as smart sensors and real-time data analytics, allows for continuous monitoring and rapid adjustments, ensuring that production remains aligned with demand and resource availability.

Streamlining Operations and Supply Chain Management

Optimizing industrial operations extends beyond the factory floor, encompassing the entire supply chain. Effective supply chain management is crucial for ensuring that raw materials arrive on time, finished products are delivered efficiently, and inventory levels are maintained at optimal points. This involves meticulous planning, robust logistics, and seamless coordination across various enterprise functions. Companies are increasingly leveraging digital platforms to gain end-to-end visibility into their supply chains, enabling proactive problem-solving, reducing transit times, and minimizing the risks associated with disruptions. A well-managed supply chain contributes directly to cost savings and improved customer satisfaction.

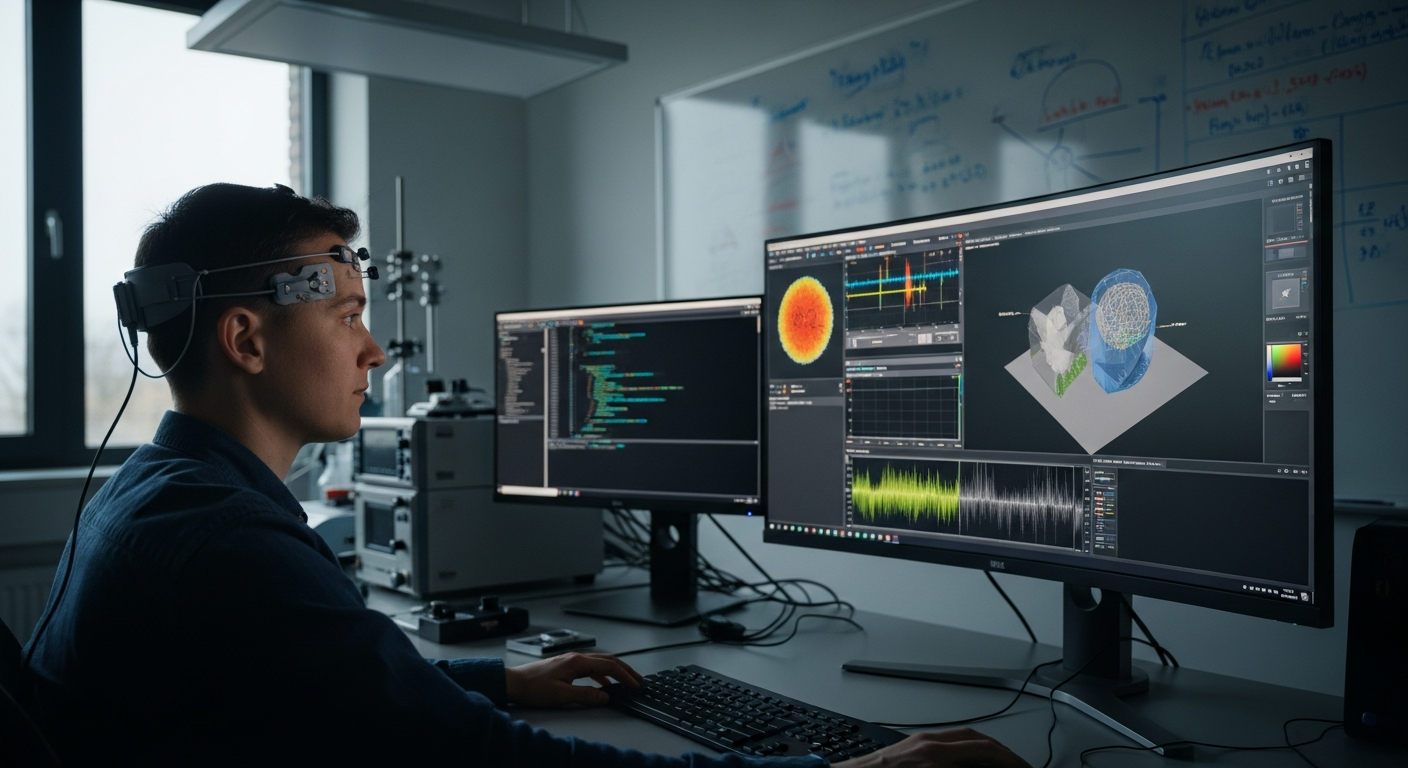

The Role of Innovation and Automation in Productivity

Innovation and automation are transformative forces driving productivity across industrial sectors. Technologies like artificial intelligence (AI), robotics, and the Internet of Things (IoT) are being integrated into various stages of production and operations. Robotic process automation (RPA) can handle repetitive tasks with greater speed and accuracy than human workers, freeing up personnel for more complex and strategic activities. Predictive analytics, powered by AI, can forecast equipment failures, optimize maintenance schedules, and improve resource allocation, leading to significant gains in overall productivity and reduced downtime. This technological advancement fosters a culture of continuous improvement.

Integrating Sustainability for Long-Term Industrial Growth

Sustainability has become a fundamental pillar of industrial development and growth. Beyond environmental responsibility, sustainable practices often lead to enhanced efficiency and long-term economic benefits. Industries are increasingly adopting strategies such as energy efficiency improvements, waste reduction and recycling programs, and the transition to renewable energy sources. Implementing circular economy principles, where materials are reused and recycled to their maximum extent, not only reduces environmental impact but also lowers material costs and enhances resource independence. This focus on sustainability aligns with global trends and consumer expectations, contributing to a company’s reputation and market position.

Strategic Approaches to Market Dynamics and Commerce

Effective strategy is essential for navigating the complex dynamics of the global market and commerce. Industrial enterprises must continuously adapt to economic shifts, changing consumer demands, and evolving trade regulations. This requires thorough market analysis, agile business models, and a willingness to innovate in product development and service delivery. Companies that strategically position themselves to anticipate and respond to market trends, invest in research and development, and foster strong relationships with partners and customers are better equipped for sustained growth. Strategic management involves making informed decisions that balance short-term gains with long-term objectives, ensuring resilience and competitiveness in a dynamic environment.

Cultivating a Culture of Continuous Improvement

Achieving sustained efficiency in industrial sectors is not a one-time project but an ongoing commitment to continuous improvement. This involves fostering a culture where every team member is encouraged to identify areas for enhancement and contribute to problem-solving. Regular performance reviews, feedback mechanisms, and training programs ensure that employees are equipped with the skills and knowledge needed to implement new technologies and optimized processes. Embracing a mindset of incremental gains, combined with a readiness to adopt breakthrough innovations, allows industrial entities to consistently elevate their operational standards and maintain a competitive edge in the global economy.

Driving efficiency in industrial sectors is a multifaceted endeavor that integrates technological innovation, strategic management, operational optimization, and a commitment to sustainability. By focusing on these key areas, businesses can not only enhance their productivity and profitability but also contribute to a more resilient and responsible industrial future. The continuous pursuit of efficiency remains central to successful industrial enterprise and its ability to adapt and thrive.