Engine efficiency developments in internal combustion vehicles

Internal combustion engines have powered a vast majority of the world's vehicles for over a century, undergoing continuous evolution to meet changing demands for performance, emissions reduction, and fuel economy. Despite the growing interest in electric vehicles, significant advancements in internal combustion engine technology persist. Engineers and innovators worldwide continue to refine these complex systems, pushing the boundaries of what is possible in terms of converting fuel into usable power with minimal waste. These ongoing developments are crucial for various sectors, including automotive, transport, and mobility.

How have modern automotive technologies improved engine efficiency?

Modern automotive engineering has introduced a suite of technologies that significantly enhance the efficiency of internal combustion engines. Direct injection systems, for instance, precisely deliver fuel directly into the combustion chamber, allowing for more complete combustion and better fuel economy compared to older port injection methods. Variable valve timing (VVT) and variable valve lift (VVL) systems optimize valve operation based on engine speed and load, improving airflow and combustion across different operating conditions. Turbocharging and supercharging, once primarily associated with performance, are now widely used to enable smaller engines to produce more power, a concept known as ‘downsizing’, which often results in better fuel efficiency under normal driving conditions.

Another notable development is cylinder deactivation, a technology that temporarily shuts down a portion of an engine’s cylinders when full power is not required, such as during highway cruising. This allows the remaining cylinders to operate at higher loads, where they are more efficient, thereby reducing fuel consumption. These technological advancements collectively contribute to a more optimized and responsive power unit, directly impacting the overall efficiency of cars, trucks, and other motor vehicles.

What role do fuel systems play in enhancing fuel efficiency?

The evolution of fuel systems has been central to improving internal combustion engine efficiency. Beyond direct injection, advanced electronic control units (ECUs) meticulously manage fuel delivery, ignition timing, and air-fuel ratios in real-time. These sophisticated systems use a myriad of sensors to monitor engine parameters, ensuring optimal combustion under varying conditions. Lean-burn technologies, though challenging to implement due to emissions regulations, aim to operate with a higher air-to-fuel ratio, potentially offering greater efficiency.

Furthermore, modern fuel systems integrate with other vehicle systems to maximize efficiency. Stop-start systems, for example, automatically shut off the engine when the vehicle is stationary and restart it when the driver intends to move. This simple yet effective innovation significantly reduces fuel consumption and emissions in urban driving scenarios. The continuous refinement of fuel pumps, injectors, and fuel lines also plays a subtle but important role in ensuring consistent and efficient fuel flow, contributing to the overall performance and economy of the engine.

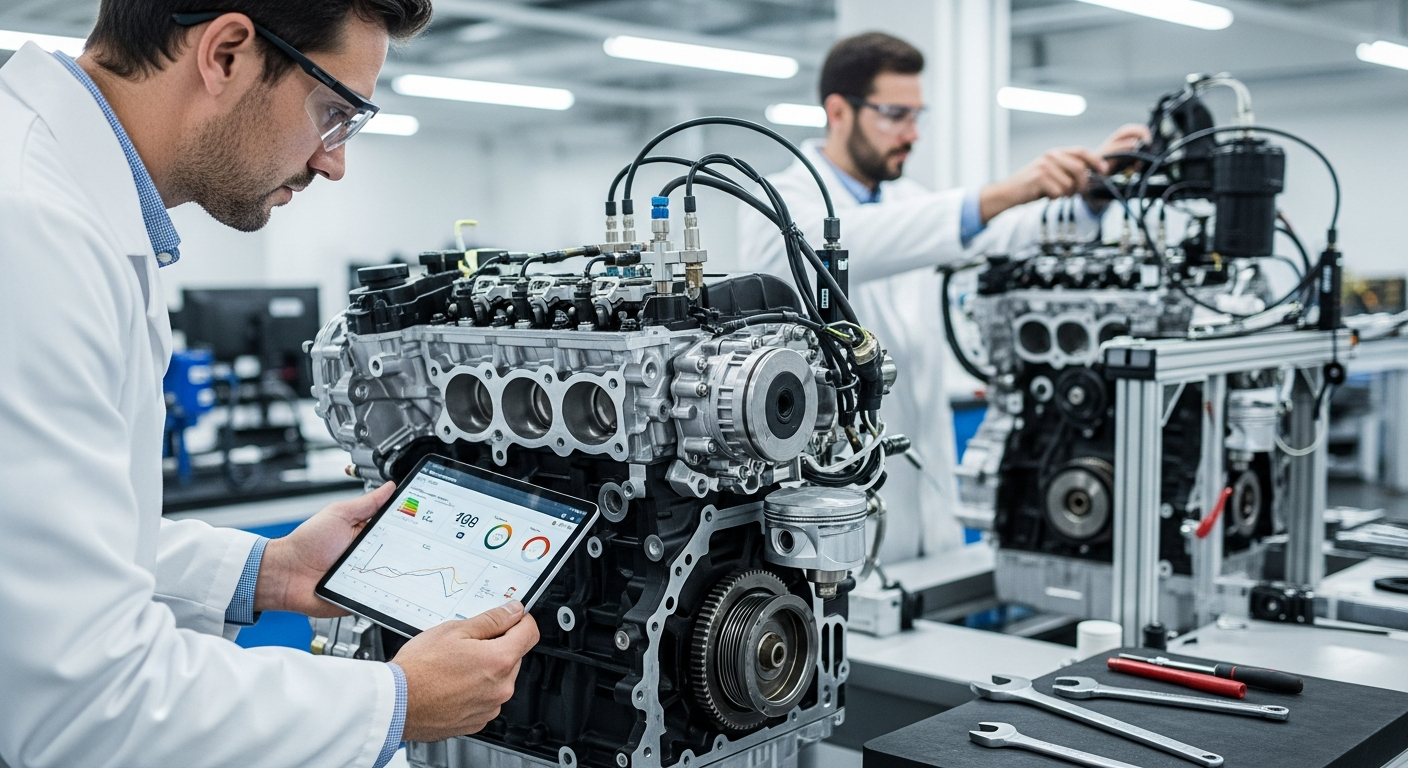

How does engineering contribute to internal combustion engine performance and efficiency?

Engineering principles are fundamental to every aspect of internal combustion engine design and manufacturing, directly influencing both performance and efficiency. The use of lightweight materials, such as aluminum alloys and composites, in engine blocks, cylinder heads, and other components reduces overall vehicle weight, which in turn demands less energy to move, leading to improved fuel economy. Minimizing internal friction within the engine is another critical area of engineering focus. Advancements in lubricants, bearing designs, and piston ring technologies reduce parasitic losses, allowing more of the engine’s power to be transmitted to the wheels.

Thermal management systems have also seen significant innovation. Efficient cooling systems and advanced heat recovery techniques aim to maintain optimal engine operating temperatures while also potentially converting waste heat into usable energy. Precision manufacturing processes ensure tighter tolerances and higher quality components, which contribute to better sealing, reduced wear, and ultimately, enhanced long-term efficiency and reliability. These engineering efforts are vital for the sustained development of automotive and transport systems.

What innovations are shaping the future of internal combustion engine design?

The future of internal combustion engine design is being shaped by ongoing innovation, even as the industry explores electric alternatives. Research into alternative combustion cycles, such as the Atkinson and Miller cycles, aims to achieve higher thermal efficiency by modifying valve timing to create a longer expansion stroke than compression stroke. While these cycles typically result in lower power density, they are often paired with turbocharging to compensate, offering a balance of power and efficiency, especially in hybrid electric vehicles.

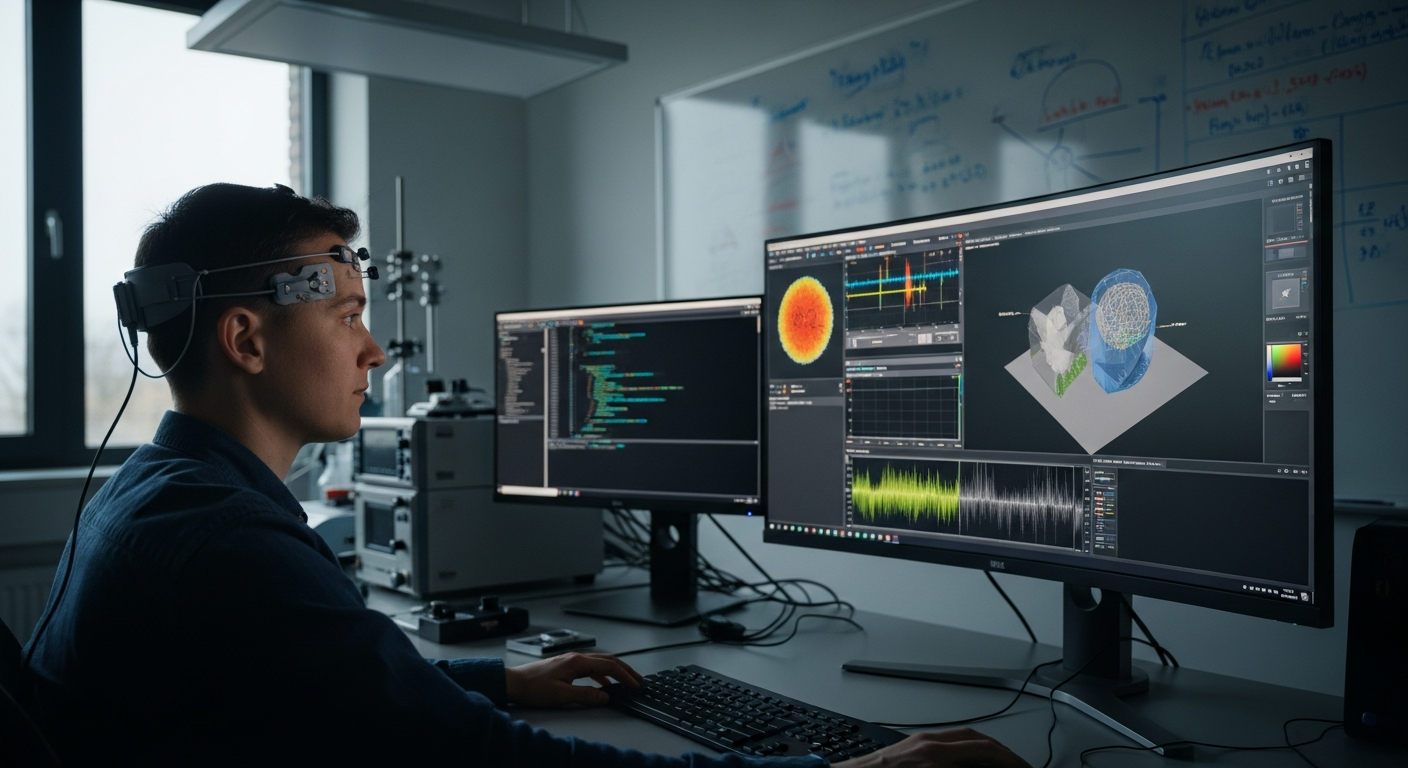

Another significant trend is the integration of internal combustion engines with electric powertrain components in hybrid vehicles. This hybridization allows the internal combustion engine to operate more frequently in its most efficient range, with the electric motor assisting during acceleration and regenerative braking recovering energy. Advanced control units, leveraging sophisticated algorithms and artificial intelligence, are becoming increasingly complex, enabling even finer optimization of engine parameters for both efficiency and emissions control. Materials science continues to evolve, promising new alloys and coatings that can withstand higher temperatures and pressures, further pushing the boundaries of engine design and performance for future mobility solutions.

In conclusion, internal combustion engines continue to be a focus of significant engineering and technological innovation. Developments in fuel systems, material science, combustion processes, and electronic controls have collectively pushed the boundaries of efficiency and performance. These ongoing advancements ensure that internal combustion engines remain a vital component of the global transport landscape, even as the industry transitions towards a more diverse range of propulsion technologies. The drive for greater efficiency reflects a commitment to sustainable mobility and responsible resource use across the automotive sector.