Leveraging Data for Enhanced Manufacturing Productivity

In today's dynamic industrial landscape, the strategic application of data is transforming how manufacturing operations are conducted. Businesses are increasingly recognizing data as a crucial asset for optimizing processes, improving decision-making, and driving significant gains in productivity. Understanding how to effectively harness this data is key for maintaining competitiveness and fostering innovation across the entire enterprise.

The manufacturing sector is undergoing a profound transformation, driven by the increasing availability and sophisticated analysis of operational data. From the factory floor to the global supply chain, data provides insights that can unlock new levels of efficiency and innovation. By collecting, processing, and interpreting this information, organizations can make more informed decisions, predict potential issues, and continuously refine their production processes.

The Role of Data Analytics in Manufacturing Operations

Data analytics is fundamental to modern manufacturing, offering a granular view of every operational aspect. By analyzing data from machinery, production lines, and quality control systems, manufacturers can identify bottlenecks, predict equipment failures, and optimize machine performance. This approach enables proactive maintenance schedules, reduces downtime, and ensures that production processes run smoothly and efficiently. Real-time data dashboards provide immediate feedback, allowing managers to make swift adjustments and maintain high levels of operational control.

Optimizing Supply Chains and Logistics through Data

Effective supply chain management and logistics are critical components of manufacturing success. Data plays a pivotal role in optimizing these areas by providing visibility into inventory levels, transportation routes, and supplier performance. Predictive analytics can forecast demand fluctuations, helping to prevent overstocking or stockouts. By analyzing logistics data, companies can identify the most efficient shipping methods, reduce transportation costs, and improve delivery times, thereby enhancing overall supply chain resilience and responsiveness.

How Automation and Robotics Enhance Production Efficiency

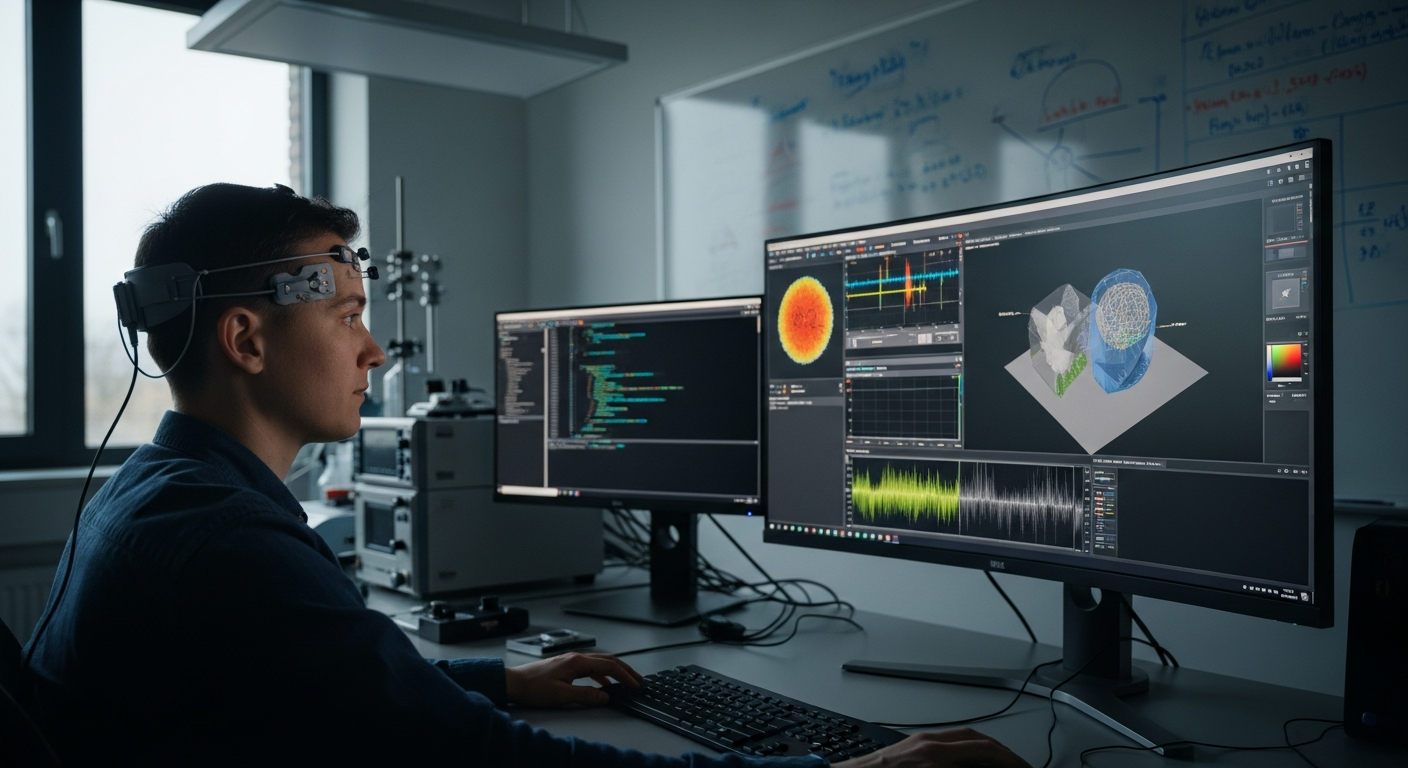

Automation and robotics are integral to boosting production efficiency in modern factories. Data serves as the backbone for these technologies, guiding robotic movements, coordinating automated processes, and ensuring precision in manufacturing tasks. Sensor data from automated systems allows for continuous monitoring and adjustment, leading to higher product quality and reduced waste. The integration of data with automation also facilitates mass customization, enabling factories to produce diverse products efficiently while maintaining high standards.

Digitalization’s Impact on Manufacturing Productivity

Digitalization encompasses the broader adoption of digital technologies to transform business processes, culture, and customer experiences. In manufacturing, this translates to creating connected ecosystems where machines, systems, and people communicate seamlessly. Digital twins, predictive maintenance, and cloud-based platforms are examples of digitalization efforts that leverage data to enhance productivity. This interconnectedness allows for comprehensive oversight, rapid problem-solving, and the agile adaptation of production strategies to market changes, driving significant improvements in overall enterprise productivity.

| Product/Service Category | Example Providers/Types | Cost Estimation (General) |

|---|---|---|

| Data Analytics Platforms | Cloud-based SaaS, On-premise solutions | Variable, depending on scale, features, and data volume |

| Industrial IoT Sensor Systems | Specialized hardware vendors | Moderate to High, based on sensor density and complexity |

| Automation & Robotics Software | PLC/SCADA systems, Robotic OS | Significant, including licensing, integration, and customization |

| Workforce Training & Skills | Consulting firms, E-learning platforms | Moderate, ongoing investment in human capital |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Investment Considerations for Data-Driven Manufacturing Solutions

Implementing data-driven solutions in manufacturing involves various investment considerations beyond direct software or hardware costs. Companies need to account for expenses related to data infrastructure, such as cloud storage and processing power, as well as the integration of new systems with existing legacy infrastructure. Significant investment is also required for workforce training to ensure employees have the skills to operate and manage these advanced technologies. While initial outlays can be substantial, the long-term benefits in terms of increased efficiency, reduced waste, and enhanced productivity often lead to a strong return on investment.

By embracing data-driven strategies, manufacturers can gain a competitive edge in a globalized market. The ability to collect, analyze, and act upon insights derived from operational data empowers businesses to optimize every facet of their production, from raw material procurement to final product delivery. This continuous improvement cycle, fueled by intelligent data use, paves the way for more resilient, efficient, and innovative industrial operations.