The Evolution of Global Manufacturing Practices

Global manufacturing has undergone a profound transformation, evolving from rudimentary craft production to highly sophisticated, interconnected systems. This journey reflects centuries of innovation, technological advancement, and strategic shifts that have reshaped economies and supply chains worldwide. Understanding this evolution is key to appreciating the complexities and opportunities within today's industrial landscape.

The landscape of global manufacturing has been continuously reshaped by technological advancements, economic shifts, and strategic innovations. From localized craft production to the intricate global networks seen today, the journey reflects a relentless pursuit of efficiency, scale, and market responsiveness. This evolution has fundamentally altered how goods are conceived, produced, and delivered across continents, impacting every facet of business and industrial operations.

From Traditional Production to Modern Manufacturing

The earliest forms of manufacturing involved skilled artisans and localized production, typically serving immediate community needs. The Industrial Revolution marked a pivotal shift, introducing machinery and the factory system, which enabled mass production and standardized goods. This era laid the groundwork for modern manufacturing, emphasizing economies of scale and centralized operations. Early automation began to emerge, improving output and reducing reliance on manual labor for repetitive tasks, setting the stage for more complex industrial processes.

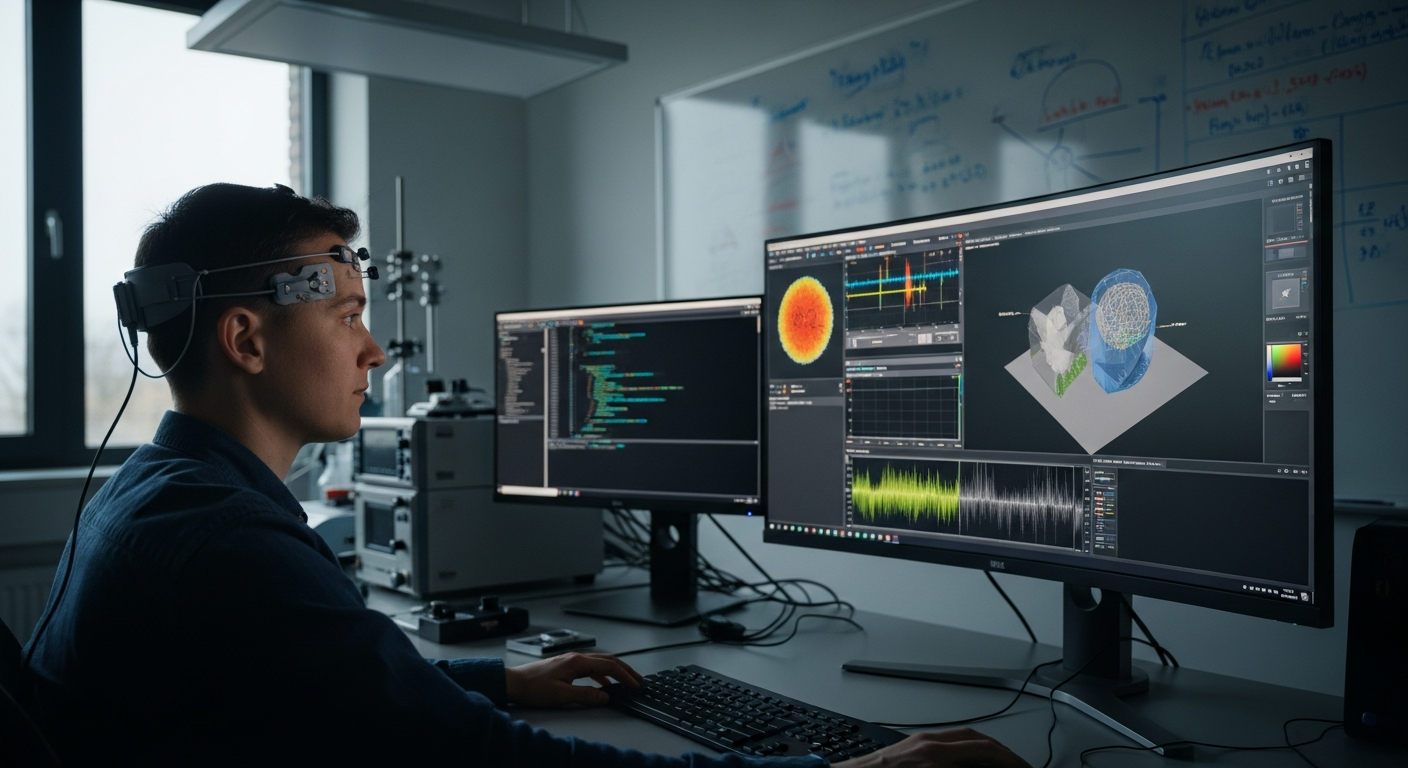

The Role of Technology and Automation in Operations

Contemporary manufacturing is characterized by the pervasive integration of advanced technology and sophisticated automation. Robotics, artificial intelligence, and the Internet of Things (IoT) have revolutionized factory operations, enabling precision, speed, and continuous monitoring. This level of automation not only boosts efficiency but also enhances safety and product quality. The ability to collect and analyze vast amounts of data allows for predictive maintenance, optimized resource allocation, and real-time adjustments, driving significant improvements in overall productivity and reducing waste.

Innovations in Global Supply Chain and Logistics

The complexity of modern manufacturing is intrinsically linked to the evolution of supply chain and logistics management. As production facilities became geographically dispersed and markets expanded, the need for robust and responsive global supply networks grew exponentially. Innovation in transportation, information technology, and warehousing has facilitated the seamless movement of raw materials and finished goods across borders. Concepts like just-in-time (JIT) delivery and lean manufacturing have become integral to maintaining competitive advantage, minimizing inventory costs, and ensuring timely delivery to consumers worldwide. Digitalization plays a critical role in orchestrating these intricate networks.

Strategic Management for Enterprise Growth

For any enterprise to thrive in the dynamic global market, effective strategy and management are paramount. Leaders must navigate geopolitical shifts, economic fluctuations, and rapidly changing consumer demands. Strategic decisions involve optimizing production locations, sourcing materials sustainably, and investing in new technologies to maintain a competitive edge. The focus has shifted from mere cost reduction to fostering long-term growth through innovation, brand building, and cultivating resilient supply chain partnerships. Sound management practices ensure that operations are aligned with overarching business objectives and contribute to overall economy and productivity.

Future Development and Digital Transformation in Manufacturing

The future development of global manufacturing is defined by ongoing digitalization and continuous innovation. Industry 4.0, characterized by cyber-physical systems, cloud computing, and advanced analytics, is transforming factories into smart, interconnected environments. These advancements promise even greater efficiency, flexibility, and customization capabilities. The integration of augmented reality (AR) and virtual reality (VR) in training and design, along with the increasing adoption of sustainable production methods, will continue to shape how commerce and industry operate, driving the next wave of industrial evolution.

In conclusion, the evolution of global manufacturing practices represents a continuous journey of adaptation and advancement. From early industrialization to the current era of digitalization and smart factories, the core drivers have been the pursuit of greater efficiency, productivity, and responsiveness to market demands. This ongoing transformation underscores the critical interplay between technology, strategy, and effective management in shaping the future of industrial development worldwide.