Unraveling the Potential of Industrial Internet of Things (IIoT) in Smart Factories

**Introduction** The increasing industrial digitization is paving the way for newer concepts like Smart Factories. Herein, the Industrial Internet of Things (IIoT) is playing a key role. This article uncovers the potential of IIoT in transforming traditional factories into smart ones.

Background: Industrial Internet of Things

The IIoT is an extension of the Internet of Things (IoT) that involves the use of internet-connected machinery and devices in industrial sectors. The concept of IIoT emerged nearly a decade ago. It was part of a broader movement towards the digitization of industry, often referred to as Industry 4.0. IIoT brings together the principles of machine learning and big data technology, harnessing the sensor data, machine-to-machine communication, and automation technologies that have existed in industrial settings for years.

Current Trends: IIoT in Smart Factories

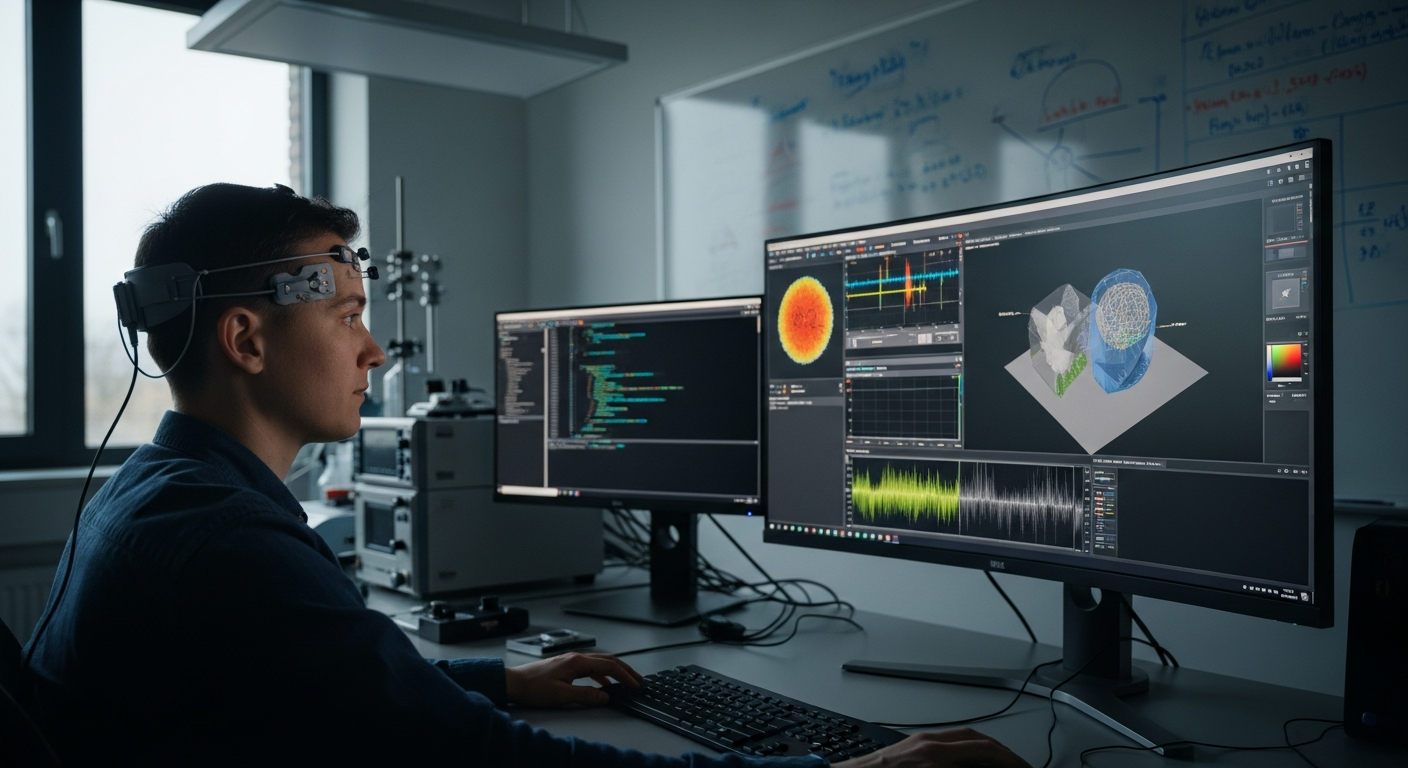

Smart factories use IIoT to create a digital representation of the physical world. This digital twin allows for data analysis and system monitoring. The use of IIoT in smart factories offers several benefits:

- Increased Efficiency: IIoT devices can monitor and optimize production processes in real-time, leading to significant efficiency gains.

- Predictive Maintenance: By analyzing data from sensors, IIoT can predict equipment failures before they occur, allowing for scheduled maintenance and minimizing downtime.

- Improved Safety: IIoT can help improve worker safety by monitoring environmental conditions and alerting workers to potential hazards.

However, the adoption of IIoT in smart factories also presents challenges, such as data security concerns and a need for skilled workers who can manage and interpret the data produced by IIoT devices.

Practical Applications: Case Studies

- BMW: The German car manufacturer uses IIoT in its factories for predictive maintenance. Sensors on its production lines predict potential failures before they occur, reducing downtime.

- GE Aviation: The company uses IIoT sensors on its aircraft engines to collect data about engine performance. This data is analyzed to optimize maintenance schedules and improve fuel efficiency.

Practical Insights

- Implementing IIoT in factories requires careful planning and a clear understanding of the potential benefits and challenges.

- Employee training is crucial to ensure that workers can effectively use IIoT technology.

- Security measures should be in place to protect sensitive data collected by IIoT devices.

Conclusion

The Industrial Internet of Things (IIoT) is a transformative technology that has the potential to revolutionize the way factories operate. However, realizing this potential requires careful planning, effective employee training, and robust security measures. By understanding and addressing these considerations, factories can leverage IIoT to become smarter, more efficient, and more productive.